Principle

Electrolysis principle for trace moisture measurement in gas was successfully tested and applied to trace moisture measurement by Keide in 1959. This method provides a continuous industrial measurement solution for trace moisture in non-alkaline gases, which can continuously, online and real-time monitor the trace moisture in various industrial processes.Belongs to the absolute value of the direct measurement of moisture!

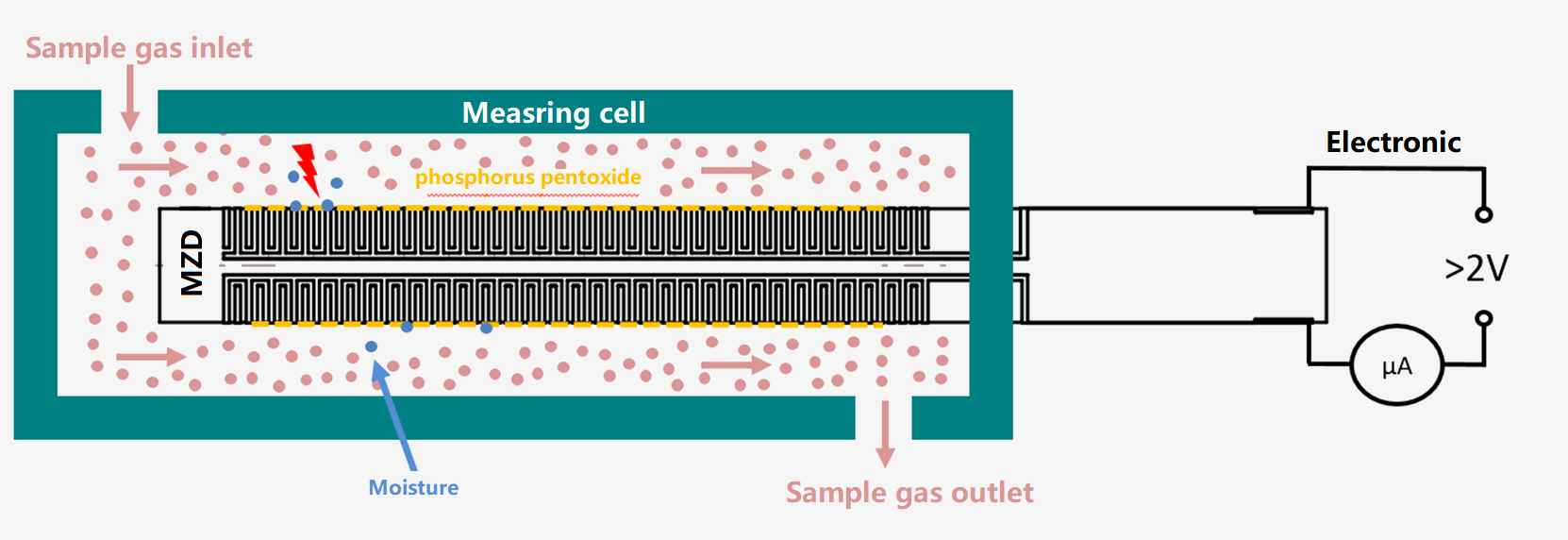

The sensor pillar is plated with parallel spiral platinum layer as the electrode, and the hydrated phosphorus pentoxide film is coated between the platinum layer. Phosphorus pentoxide has a strong water absorption, when chlorine gas flows steadily through the sensor flow cell, where the water is absorbed to generate phosphoric acid, the reaction formula is as follows:

P2O5 + 3H2O → 2H3PO4

At the same time, between the two platinum layers to plus DC voltage, that has the electrolysis reaction, phosphoric acid is reductively decomposed into oxygen,chlorine, phosphorus pentoxide.The reaction formula is as follows:

4H3PO4→6H2+3O2+2P2O5

When the absorption and electrolysis reach a balance, the water entering the electrolytic cell is absorbed by the phosphorus pentoxide film and electrolyzed. According to Faraday's law of electrolysis and gas law, it can be deduced that the electrolysis current of water is proportional to the water content of the gas sample. The specific calculation relationship is as follows:

I = QPT0FU×10-4/3P0TV0

I-electrolysis current of water, μA;

U-water content of the gas sample μL/L (volume ratio);

Q-gas sample flow mL/min;

P—environmental pressure, Pa;

T0=273.15K;

F=96485C;

P0=101325 Pa;

T—the absolute temperature of the environment, K;

V0=22.4L/mol.

The electrolysis moisture analyzer is an absolute measurement method, which is stable and does not drift. It can be used for acid gas such as chlorine, hydrogen chloride, hydrogen sulfide, hydrogen fluoride, sulfur dioxide, sulfur trioxide, or used for air, nitrogen, hydrogen, oxygen, argon, helium, neon, carbon monoxide, carbon dioxide, sulfur hexafluoride , Methane, ethane, propane, butane, natural gas and other neutral gases, but not suitable for alkaline gases that react with P2O5, such as ammonia.

The phosphorous pentoxide coating needs to be regenerated regularly, and the maintenance cost is very low, usually using phosphoric acid regeneration every 3 to 6 months. When used in high-humidity situations, the life of the phosphorus pentoxide coating will be shortened, and the regeneration cycle needs to be shortened.

Ceramic flat plate sensor

Based on the glass sensor, MZD have developed a ceramic sensor that can realize standardized and automation production. Positive and negative platinum layers are plated on ceramic flat plates. The contact area between the platinum layer and the sample gas is larger, the reaction is faster, and the measurement is more stable and reliable.

Highlights:

• No calibration required*

• Range: 0 ~ 1 bis 2000ppm*

• Quick response: T90(up) < 5s

• High accuracy and repeatability: Accuracy <2%FS, Repeatability <±0.5%FS

• Flow: 20l/h

• Rugged and durable design

• Long-life ceramic sensor

Main applications:

• Lithium battery

• Vacuum drying oven manufacturer

• Vacuum glove box manufacturer

• Universities and scientific research institutions (nuclear industry/new energy materials)

• Metal heat treatment/welding

• OLED/capacitor/HID lamp and electronics

• Fine Chemicals/Pharmaceuticals

• Vacuum drying box/glove box moisture meter and OEM