Description

The Optical oxygen sensor is cost-effective and suitable for stable and continuous measurement of the percentage oxygen content of most gases.

This principle is very robust. It shows virtually no interferences to other gases (except Cl2 and NO2), has a very low drift, and the sensor is fully solid-state. It does not deplete over time, unlike galvanic oxygen sensors with their limited shelf life. Optics and electronics are hermetically sealed from the measured gas. For typical indoor environmental conditions, a 10-year operating life is expected.

Principle

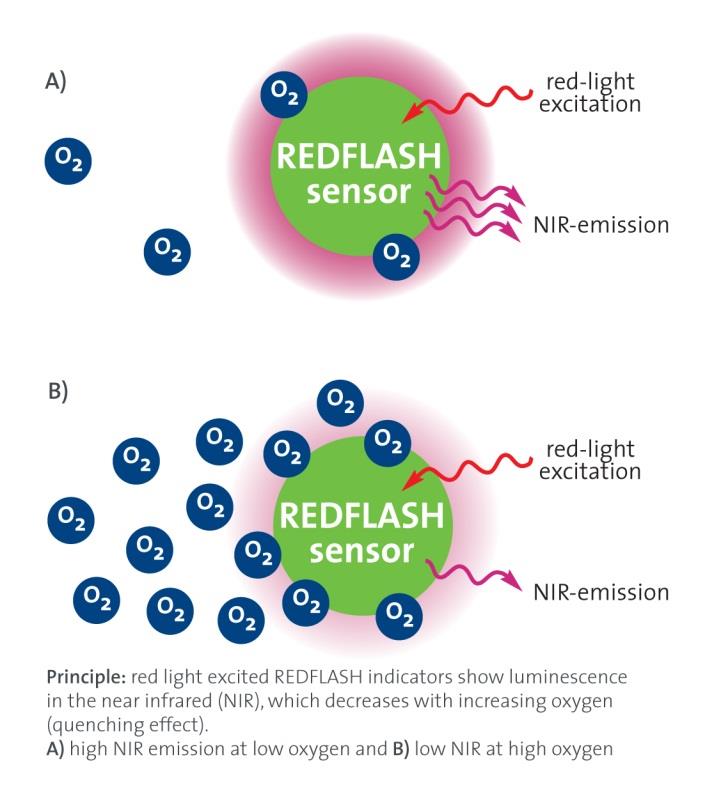

The new Optical technology is based on the unique oxygen-sensitive REDFLASH indicator showing excellent brightness. The measuring principle is based on the quenching of the REDFLASH indicator luminescence caused by collision between oxygen molecules and the REDFLASH indicator immobilized on the sensor tip or surface. The REDFLASH indicators are excitable with red light (more precisely: orange-red at a wavelength of 610-630 nm) and show an oxygen-dependent luminescence in the near infrared (NIR, 760-790 nm).

The Optical technology impresses by its high precision, high reliability, low power consumption, low cross-sensitivity, and fast response times. The red-light excitation significantly reduces interferences caused by autofluorescence and reduces stress in biological systems. The REDFLASH indicators show much higher luminescence brightness than competing products working with blue light excitation. Therefore, the duration of the red flash for a single oxygen measurement could be decreased from typically 100 ms to now typically 10 ms, significantly decreasing the light dose exposed to the measuring setup. Further, due to the excellent luminescence brightness of the REDFLASH indicator, the actual sensor matrix can be now prepared much thinner, leading to fast response times of the oxygen sensors.

The measuring principle is based on a sinusoidally modulated red excitation light. This results in a phase-shifted sinusoidally modulated emission in the NIR. Optical oxygen sensor measures this phase shift (termed "dphi" in the software). The phase shift is then converted into oxygen units based on the Stern-Vollmer-Theory.

Application

▲ASU(Air separation uint)

▲Fertilizer, Chemical, Pharmaceutical industry

▲Petroleum and Petrochemical industry

▲Semiconductor industry

▲Food and beverage industry

▲Metallurgical iron and steel industry

▲Nuclear,heat treatment, welding protection

▲Aerospace and defense

▲Biological research

▲Light bulb manufacturing, semiconductor

▲Optical fiber research

▲Inert gas generator

▲Glass manufacturing

▲Special gas

▲Laboratory

▲Flare monitoring

▲Extraction and processing of natural gas

▲Environmental area monitoring

▲Anesthesia, breathing and prenatal care

Advantage

★High-accuracy measurement

★Low drift

★Rugged and durable design

★Long life

★Fast response (t63<2s)

★Temperature compensation

★Stainless steel sintered filtration (membrane filtration optional)

Measurement components and ranges

• O2: 0 ~ 100%