The trace moisture analyzer is suitable for stable and continuous trace moisture measurement in strongly corrosive acidic gases and most neutral gases.

Description

Electrolysis principle for trace moisture measurement in gas was successfully tested and applied to trace moisture measurement by Keide in 1959. This method provides a continuous industrial measurement solution for trace moisture in non-alkaline gases, which can continuously, online and real-time monitor the trace moisture in various industrial processes.Belongs to the absolute value of the direct measurement of moisture!

Working principle

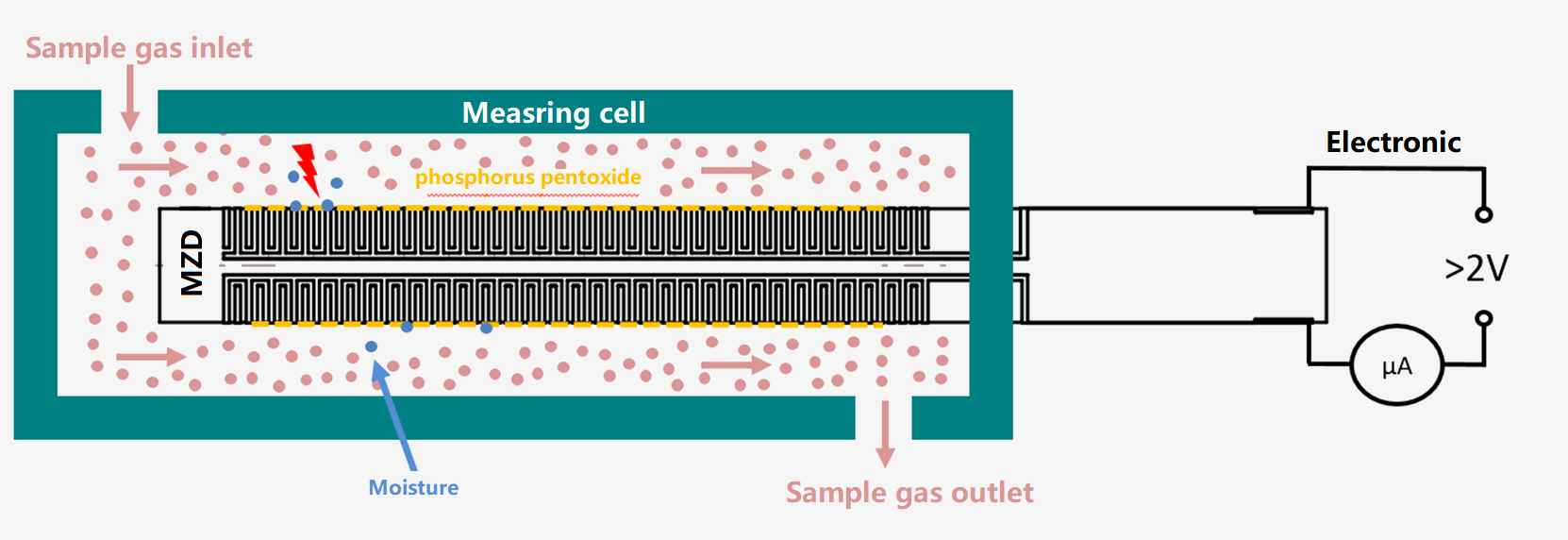

The sensor pillar is plated with parallel spiral platinum layer as the electrode, and the hydrated phosphorus pentoxide film is coated between the platinum layer. Phosphorus pentoxide has a strong water absorption, when chlorine gas flows steadily through the sensor flow cell, where the water is absorbed to generate phosphoric acid, the reaction formula is as follows:

P2O5 + 3H2O → 2H3PO4

At the same time, between the two platinum layers to plus DC voltage, that has the electrolysis reaction, phosphoric acid is reductively decomposed into oxygen,chlorine, phosphorus pentoxide.The reaction formula is as follows:

4H3PO4→6H2+3O2+2P2O5

When the absorption and electrolysis reach a balance, the water entering the electrolytic cell is absorbed by the phosphorus pentoxide film and electrolyzed. According to Faraday's law of electrolysis and gas law, it can be deduced that the electrolysis current of water is proportional to the water content of the gas sample. The specific calculation relationship is as follows:

I = QPT0FU×10-4/3P0TV0

I-electrolysis current of water, μA;

U-water content of the gas sample μL/L (volume ratio);

Q-gas sample flow mL/min;

P—environmental pressure, Pa;

T0=273.15K;

F=96485C;

P0=101325 Pa;

T—the absolute temperature of the environment, K;

V0=22.4L/mol.

The electrolysis moisture analyzer is an absolute measurement method, which is stable and does not drift. It can be used for acid gas such as chlorine, hydrogen chloride, hydrogen sulfide, hydrogen fluoride, sulfur dioxide, sulfur trioxide, or used for air, nitrogen, hydrogen, oxygen, argon, helium, neon, carbon monoxide, carbon dioxide, sulfur hexafluoride , Methane, ethane, propane, butane, natural gas and other neutral gases, but not suitable for alkaline gases that react with P2O5, such as ammonia.

The phosphorous pentoxide coating needs to be regenerated regularly, and the maintenance cost is very low, usually using phosphoric acid regeneration every 3 to 6 months. When used in high-humidity situations, the life of the phosphorus pentoxide coating will be shortened, and the regeneration cycle needs to be shortened.

Installation

▲Corrosive gas: PVDF electrolytic cell, Non-corrosive gas: PVDF or SS stainless steel electrolytic cell

▲The sample gas pressure can reach 3Bar(PVDF)/10Bar(SS)

▲Stable sample gas flow rate 20Nl/h or 100Nl/h

▲Three-way valve and four-way valve operation, convenient for sensor maintenance and recoating

▲Slight positive pressure protection of compressed air in the sampling unit

▲Filter can be used for unclean gases

▲Electric heating regulator can be used for liquid chlorine evaporation

▲Vacuum pump can be used for the vacuum sample gas

▲The sample gas outlet is recommended to be discharged into the exhaust gas treatment equipment

Application

★Chlor-alkali chemical, PVC chemical industry: Trace moisture measurement in chlorine gas, liquid chlorine, hydrogen chloride, sulfur dioxide;

★Fluorine chemical industry: Trace moisture measurement in hydrogen fluoride;

★Polysilicon, organic silicon industry: Trace moisture measurement in chlorine, hydrogen chloride, silicon tetrachloride;

★Natural gas and petrochemical industry: Trace moisture measurement in natural gas, hydrogen, acetylene and other hydrocarbon gases;

★Gas industry, ASU(Air Separation Unit): Trace moisture measurement in oxygen, nitrogen, carbon dioxide, argon or other rare gases

★Freezer, Compressor: Trace moisture measurement in process gas;

★Electricity:Trace moisture measurement in SF6;

Features

• Zirconia ceramic or glass material is optional. The movable construction of electrolytic cell is easy disassembly and maintenance.

• Quick and convenient

The navigation menu contains 6 languages, which can be operated easily.

• Process safety

4.3" or 7" large size color LCD touch screen, convenient and safe touch operation and debugging

Large size screen with red flashing alarm, clearly visible from long distances and in dark areas

Alarm immediately, safe the process

• Alarm event record

Real-time data curve display

Record function for up to 6000 alarms

• Expert calibration function

Multi-point calibration function up to 9 point

• Powerful self-diagnosis function

Built-in flow status monitoring or mass flow measurement and controller

Built-in heartbeat monitoring function and watchdog

Monitor the status of controllers and sensors, and promptly remind customers to take necessary maintenance

High-standard hardware and software security and password protection

• Powerful control function

High(low) limit control function

Optional: Timer control(automatic cleaning) function

Optional: analog PID controller

Optional: PWM controller

• Flexible fieldbus communication functions for IOT4.0

Optional fieldbus MODBUS, HART, Foundation Fieldbus FF, PROFIBUS PA, PROFIBUS DP, etc.

• ATEX EExd II CT4 Optional

Some application case:

▲Trace moisture measurement in chlorine at the inlet of the chlorine compressor to protect the chlorine compressor.

▲Trace moisture measurement in chlorine at the outlet and the final outlet of the chlorine compressor to protect the chlorine compressor.

▲Monitor the leakage of the precooler to protect the chlorine compressor.

▲Monitor the accuracy of the dew point analyzer at the outlet of the freezer.

Measurement components and ranges

• H2O: 0~1ppm/10ppm/100ppm/500ppm(Max.2500ppm)

Measurement unit can be ppm Volume, or ppm Weight which is based on the gas molar weight!

Product datasheet: ppm/ppb Mositure Analyzer(Trace Moisture in Gas),SMART-MT ![]() , if you need more information, please contact us at info@mzdd.de.

, if you need more information, please contact us at info@mzdd.de.

trace moisture analyzer,moisture analyzer, Chlorine, hydrogen chloride, hydrogen fluoride, natural gas, sulfur dioxide, glove box,ppm moisture analyzer,ppb moisture analyzer,P2O5 moisture sensor, P2O5 moisture analyzer, Medical oxygen analyzer