Infrared photometry Analyzer(NDIR)

Working Principle:

Various polyatomic gases (CO, CO2, CH4, etc.) absorb infrared light not the whole band, but only a part of the band, which are called characteristic absorption bands. Different gases have different infrared absorption wavelengths. Infrared photometry analyzer is based on the characteristic of selective absorption of infrared radiation at different wavelengths of certain gases. When infrared light pass through a gas mixture, the measured component of the gas absorbs the infrared radiation energy, and this change is related to the concentration of the measured gas component, so that the concentration of the measured component can be determined.

Since asymmetric polyatomic molecular gases (e.g. CO2, NO, etc.) have selective absorption of infrared light at specific wavelengths, the decrease in intensity of light when non-dispersive infrared (NDIR) passes through a sample gas is proportional to the number of molecules. According to the Lambert-Beer absorption law, the concentration of a gas can be determined from the change in light intensity. A = lg(1/T) = K*L*c

where

A------- absorbance

T------- transmission ratio (transmittance), the intensity of the outgoing light (I) over the intensity of the incoming light (I0).

K------- molar absorbance coefficient, which is related to the nature of the absorbing substance and the wavelength λ of the incident light.

c------- concentration of the absorbing substance, i.e., the concentration of the sample gas, in mol/L

L------- thickness of the absorbing layer (length of the gas chamber) in cm.

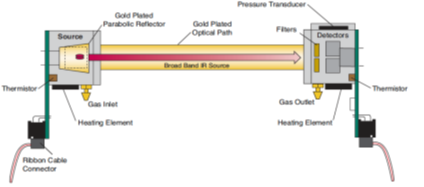

Work detection structure

Infrared photometry analyzer uses broadband radiation sources (thermal emitters). This radiation immediately reaches the measuring cuvette. There, specific spectral ranges are absorbed from the broadband spectrum of the radiation source. The measuring detector which contains at least 2 separate channels, is located at the end of the measuring cuvette. In the simplest case the measuring channel has an interference filter placed in front of the detector. The reference detector also has an interference filter in front of the detector, but with a spectral transmission range (approx. 4 µm) where no absorption takes place. Afterwards a detector measures the specific radiation absorption. The evaluation electronics use the two signals to calculate the gas concentration in the measuring cuvette. Alternatively, a detector with several measuring channels can be placed at the end of the measuring cuvette, so that 3 components to be recorded simultaneously.

Infrared gas analyzer can be used to analyze various polyatomic gases, such as: C2H2, C2H4, C2H5OH, C3H6, C2H6, C3H8, NH3, CO2, CO, CH4, SO2, etc.. It cannot be used to analyze polyatomic gases composed of the same atom and inert gases, such as: N2, Cl2, H2, O2, He, Ne, Ar, etc.

The effect of moisture on infrared instruments

As the moisture in flue gas emissions, especially gaseous water is the main interfering substance affecting the determination of sulfur dioxide and nitrogen oxides, which directly affects the measurement accuracy of the instrument. This is the main reason why some of the infrared gas analyzers in laboratory conditions using standard gas calibration when qualified in the field test but can not meet the requirements.

The impact of test resolution on infrared instruments

With the strengthening of pollutant management a large number of desulfurization and denitrification devices have been applied to the actual emission concentration of pollutants is also becoming smaller and smaller. Many instruments will use different algorithms to improve the stability of the zero point to ensure that the zero point fluctuations are reduced; and as mentioned before, in order to compensate for the impact of moisture interference will also use the zero point compensation method. The direct result of this is that the instrument does not respond when conducting low concentration tests near the zero point.

Measured gases and ranges:

vCO: 0~200ppm up to 100%(Vol)

vCO2: 0~50ppm up to 100%(Vol)

vCnHm: 0~500ppm up to 100%(Vol)

vN2O: 0~500ppm up to 100%(Vol)