Overview

Infrared photometry analyzer uses high-performance light emitting diodes (IR-LED) and thermal micro radiators which are suitable to gas measurement technology. It has high stability and a low detection limit. In the spectral range from 2 μm to 12 μm, carbon dioxide(CO2), carbon monoxide(CO), hydrocarbons(CmHn) and nitrous oxide(N2O) can be measured.

Principle

Various polyatomic gases (CO, CO2, CH4, etc.) absorb infrared light not the whole band, but only a part of the band, which are called characteristic absorption bands. Different gases have different infrared absorption wavelengths. Infrared photometry analyzer is based on the characteristic of selective absorption of infrared radiation at different wavelengths of certain gases. When infrared light pass through a gas mixture, the measured component of the gas absorbs the infrared radiation energy, and this change is related to the concentration of the measured gas component, so that the concentration of the measured component can be determined.

Since asymmetric polyatomic molecular gases (e.g. CO2, NO, etc.) have selective absorption of infrared light at specific wavelengths, the decrease in intensity of light when non-dispersive infrared (NDIR) passes through a sample gas is proportional to the number of molecules. According to the Lambert-Beer absorption law, the concentration of a gas can be determined from the change in light intensity. A = lg(1/T) = K*L*c

where

A------- absorbance

T------- transmission ratio (transmittance), the intensity of the outgoing light (I) over the intensity of the incoming light (I0).

K------- molar absorbance coefficient, which is related to the nature of the absorbing substance and the wavelength λ of the incident light.

c------- concentration of the absorbing substance, i.e., the concentration of the sample gas, in mol/L

L------- thickness of the absorbing layer (length of the gas chamber) in cm.

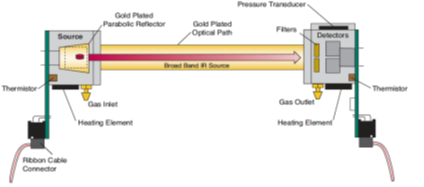

Work detection structure

Infrared photometry analyzer uses broadband radiation sources (thermal emitters). This radiation immediately reaches the measuring cuvette. There, specific spectral ranges are absorbed from the broadband spectrum of the radiation source. The measuring detector which contains at least 2 separate channels, is located at the end of the measuring cuvette. In the simplest case the measuring channel has an interference filter placed in front of the detector. The reference detector also has an interference filter in front of the detector, but with a spectral transmission range (approx. 4 µm) where no absorption takes place. Afterwards a detector measures the specific radiation absorption. The evaluation electronics use the two signals to calculate the gas concentration in the measuring cuvette. Alternatively, a detector with several measuring channels can be placed at the end of the measuring cuvette, so that 3 components to be recorded simultaneously.

Infrared gas analyzer can be used to analyze various polyatomic gases, such as: C2H2, C2H4, C2H5OH, C3H6, C2H6, C3H8, NH3, CO2, CO, CH4, SO2, etc.. It cannot be used to analyze polyatomic gases composed of the same atom and inert gases, such as: N2, Cl2, H2, O2, He, Ne, Ar, etc.

Application

• Environmental and Process Measurement Technology (CEM)

• Engine development

• Elemental analysis

• Industrial gas analysis

• Natural gas/biogas analysis

• Process measurement technology

• Biogas research

Features

• Linearity error: ±0.5%FS or 1 % F.S

• Sensor sample cell: aluminium/gold

• High dynamic range, 1:100

• Fast response time, t90 is about 3 s

• Convenient

The navigation menu contains 6 languages, which can be operated easily.

• Process safety

7" large size color LCD touch screen, convenient and safe touch operation and debugging

Large size screen with red flashing alarm, clearly visible from long distances and in dark areas

Alarm immediately, safe the process

• Data alarm record

Real-time data curve display

Record function for up to 6000 alarms

• Optional mass flow measurement and controller

• Expert calibration function

Multi-point calibration function up to 9 point

• Powerful self-diagnosis function

Built-in heartbeat monitoring function and watchdog

Monitor the status of analyzer and sensors, and promptly remind customers to take necessary maintenance

High-standard hardware and software security and password protection

• Powerful control function

High(low) limit control function

Optional: Timer control(automatic cleaning) function

Optional: analog PID control function

Optional: PWM control function

• Flexible fieldbus communication functions for IOT4.0

Optional fieldbus MODBUS, HART, Foundation Fieldbus FF, PROFIBUS PA, PROFIBUS DP, etc.

• ATEX / IECEx Exd II CT4 Optional

Measurement components and ranges

• CO: 0 ~ 500ppm up to 100%(Vol)

• CO2: 0 ~ 50ppm up to 100%(Vol)

• HCs: 0 ~ 1000ppm up to 100%(Vol)

• CH4: 0 ~ 1000ppm up to 100%(Vol)

• N2O: 0 ~ 100ppm up to 100%(Vol)

• SF6: 0 ~ 50ppm up to 100%(Vol)

• CF4: 0 ~ 100%(Vol)

Product datasheet: Infrared photometry analyzer ![]() , if you need more information, please contact us at sales@mzdd.de.

, if you need more information, please contact us at sales@mzdd.de.

Medical oxygen analyzer, Environmental and Process Measurement Technology (CEMS), Carbon Dioxide Analyzer, Carbon Monoxide Analyzer, Hydrocarbon Analyzer, Nitrous Oxide Analyzer, Sulfur Dioxide Analzyer,NDIR analyzer, IR analyzer