Description

SMART-OXZ percent Oxygen Analyzer uses a unique reference built-in zirconia technology, higher accuracy and repeatability oxygen measurement, no need to provide standard air and calibration.

Principle

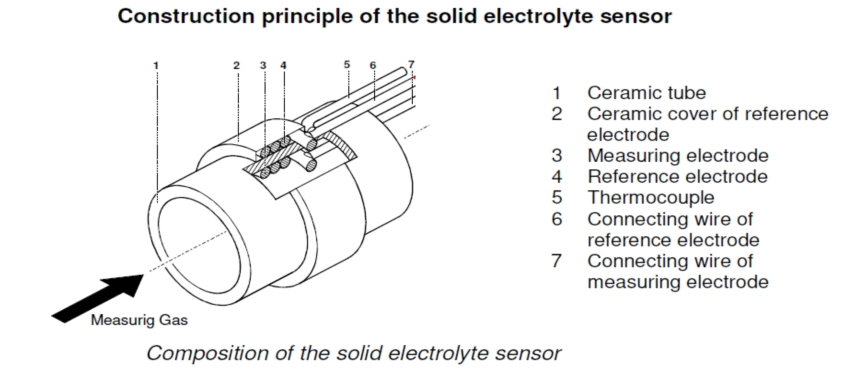

Zirconia (ZrO2) is a ceramic, doped with a certain percentage of low-valent metal oxides as stabilizers, such as calcium oxide (CaO), magnesium oxide (MgO), and yttrium oxide (Y2O3), it has high-temperature conductivity, a conductor with ionic conductive properties, and becomes a zirconia solid electrolyte. At a certain temperature, when the oxygen content in the gas on both sides of the zirconia tube is different, a typical oxygen concentration difference cell is formed.

The zirconia tube as a whole is tubular, separated by zirconia material, and a porous layer of metal is sintered on each side of the zirconia as an electrode (usually Pt is used as the electrode material). At a certain temperature (600℃~1400℃), oxygen molecules on the side with higher oxygen content are adsorbed on the electrode, making the electrode on that side positively charged and the positive or anode of the oxygen concentration difference battery. Under the catalytic action of platinum, a reduction reaction occurs and electrons are obtained to form oxygen ions. The oxygen ions migrate through the holes in the zirconia crystal to the other side where the oxygen content is lower, making that electrode negatively charged and the negative or cathode of the oxygen concentration cell. At the platinum electrode electrons are lost and oxygen molecules are formed. This creates a certain potential at the two electrodes due to the buildup of positive and negative charges, which is related to the difference in oxygen content concentration in the two measured gases of zirconia, in accordance with Nernst equation:

E=(RT/4F)*Ln(P0/P)

Where

E------- oxygen concentration difference potential (mV)

R------- gas constant 8.3145 J/mol-K

T------- zirconia probe operating temperature (K, absolute temperature) = 273.15 + t (°C)

F------- Faraday constant, 96485.3365 (C/mol)

P0------- partial pressure of oxygen in the reference gas

P ------- Oxygen partial pressure in the sample gas

The oxygen partial pressure (P) in the gas to be measured can be calculated by measuring the concentration cell potential E and the absolute temperature of the zirconia probe, and thus the oxygen concentration in the gas to be measured.

The zirconia method has high sensitivity, fast response time, wide linear range, good reproducibility and stability. The internal structure is simple and almost independent of external environmental conditions such as temperature, vibration, etc., and requires little maintenance. However, the zirconia method is not suitable for measuring oxygen concentration in reducing gases or gas samples with high reducing gas content because the oxygen concentration is affected by the reducing gas in the gas to be measured, resulting in low measurement results. The sensor life is typically 5 years or more and is typically used for oxygen content measurements at ppm, air concentration (20.64%).

Main applications of zirconia analyzer:

1. inert gas measurement of trace oxygen content, electronic semiconductor industry, air separation, steel metallurgy, chemical fertilizer, chemical industry, welding protection, etc.

2. flue gas measurement of percent oxygen content, power plants, petrochemical refining, chemical industry, iron and steel metallurgy, cement and building materials, boilers, etc.

Application

▲ASU(Air separation uint)

▲Fertilizer, Chemical, Pharmaceutical industry

▲Petroleum and Petrochemical industry

▲Semiconductor industry

▲Food and beverage industry

▲Metallurgical iron and steel industry

▲Nuclear,,heat treatment, welding protection

▲Aerospace and defense

▲Biological research

▲Light bulb manufacturing, semiconductor

▲Optical fiber research

▲Inert gas generator

▲Glass manufacturing

▲Special gas

▲Laboratory

▲Flare monitoring

▲Extraction and processing of natural gas

▲Environmental area monitoring

▲Anesthesia, breathing and prenatal care

Advantage

★Quick response

★High accuracy and repeatability

★No drift, maintenance-free, no calibration required*

★Rugged and durable design

★Easy installation

★Comfortable and friendly operation

★Long-life zirconia sensor

Features

• Quick and convenient

The navigation menu contains 6 languages, which can be operated easily.

Uses M12 connector to connect with sensor, Plug-and-play.

• Process safety

7" large size color LCD touch screen, convenient and safe touch operation and debugging

Large size screen with red flashing alarm, clearly visible from long distances and in dark areas

Alarm immediately, safe the process

Using M12 connector to connect with sensor, no risk of wrong connection

• Data alarm record

Real-time data curve display

Record function for up to 6000 alarms

• Optional mass flow measurement and controller

• Expert calibration function

Multi-point calibration function up to 9 point

• Powerful self-diagnosis function

Built-in heartbeat monitoring function and watchdog

Monitor the status of analyzer and sensors, and promptly remind customers to take necessary maintenance

High-standard hardware and software security and password protection

• Powerful control function

High(low) limit control function

Optional: Timer control(automatic cleaning) function

Optional: analog PID control function

Optional: PWM control function

• Flexible fieldbus communication functions for IOT4.0

Optional fieldbus MODBUS, HART, Foundation Fieldbus FF, PROFIBUS PA, PROFIBUS DP, etc.

• ATEX EEx II CT4 Optional

Measurement components and ranges

• O2: 0 ~ 10% / 25% / 100%

Product datasheet: Percent O2 Analyzer(Zirconia principle) ![]() , if you need more information, please contact us at info@mzdd.de.

, if you need more information, please contact us at info@mzdd.de.

Oxygen analyzer, Environmental and Process Measurement Technology (CEMS)