Water In Oil Measurement Concepts And Selection Methods

Abstract: There are a variety of methods to measure the water in oil and the appropriate method need to be selected according to the specific requirements. Based on the clarification of the concept and comparison from principle and application level, a relatively complete analysis is provided.

Introduction

With the development of the economy, the deepening of technological innovation and the refinement of production, the measurement of water in oil has become a requirement. However, before deciding which measurement method to use, it is necessary to have a clear concept of water in oil measurement, and to compare the advantages and disadvantages of various measurement methods in order to use the most suitable method to obtain the best results.

1 Basic concept and status of water in oil measurement

1.1 Basic concepts

First of all, we need to find out what is water in oil and the form in which water exists in oil.

Water has three forms: gaseous, liquid and solid. In the gaseous state, it exists in the form of water molecules, while in the liquid state and solid state, it exists in the form of chemically combined water. According to the definition of ISO3171, the existence of water in oil in the form of dissolved water, suspended water, free water. The definitions are as follows.

1) Dissolved water The water contained in the oil at the current temperature forms a solution, i.e. is dissolved in the oil. At this point the water exists in the form of water molecules.

2)Suspended water Water in oil is suspended as droplets in the oil. At this time, the water exists in the form of chemically combined water. With the change of temperature and pressure conditions, the suspended water may become dissolved water or free water.

3)Free water The water forms a stratification with the oil and usually sinks at the bottom of the oil. The water at this point exists in the hydrated water form.

4)Total water Includes the sum of all three forms of water mentioned above.

According to the definition can be seen, the first thing to understand the measured exactly the kind of water, in order to choose the right product.

1.2 Current status of water-in-oil measurement

The commonly referred to crude oil water content measures the total water content in the oil, and the measurement range is from 0% to 100%, i.e. from the oil continuous phase to the water continuous phase. It is mainly used for metering handovers, material calculations, contractual agreements, etc. There are numerous online methods of measurement in addition to laboratory methods. As for the measurement of dissolved water, it is usually used in lubricating oil systems, turbines, transformers, etc. Because of its low water content (ppm level), none of the online measurement methods for water content can effectively measure it. Therefore it is necessary to clarify the concept of measurement of water in these two types of oil and to compare the commonly used measurement methods.

2 Measurement of crude oil water content

2.1 Basic concepts

Crude oil water content measures the total water content in crude oil. The traditional measurement methods are Karl Fischer coulometric titration, distillation, centrifugation, etc., all of which are laboratory measurements, among which the accuracy of Karl Fischer method is better than other methods regardless of the water content. However, the laboratory method has its limitations, such as poor representativeness, timeliness and other problems [1].

With the development of technology, online measurement of crude oil water content has also been widely used. Various principles of measurement methods are used, among which the most widely used are: capacitance method, infrared absorption method, electromagnetic wave capacitance method, microwave absorption method, microwave resonance method, ray method, density method, etc. Each method has its own advantages and disadvantages, and all have their application occasions. The following will analyze and compare several commonly used methods to clarify the concept and choose the most appropriate method.

2.2 Online measurement methods

2.2.1 Capacitance method

The capacitance method uses the principle that the dielectric constants of water and oil are very different to measure the water content of crude oil. Since the dielectric constant of water is close to 70 and the dielectric constant of crude oil is 2~3, a small change in water content will cause a large change in the total dielectric constant. The change in dielectric constant can be reflected as a change in capacitance, and the water content can be obtained by measuring the capacitance value. The measurement circuit can be composed of a capacitive sensor and an inductor, which are connected in parallel to form a resonant circuit and loaded with an AC excitation signal with different capacitance and different impedance, and different partial voltage on it. The water content of crude oil is obtained by measuring the voltage [2].

The capacitance method instrumentation is simple and easy to install, and the accuracy will be high when used in combination with temperature and density sensors, but if the moisture content is too high (>80%), the capacitance measurement probe will be short-circuited to the pipe and the water content cannot be measured.

2.2.2 Infrared absorption method

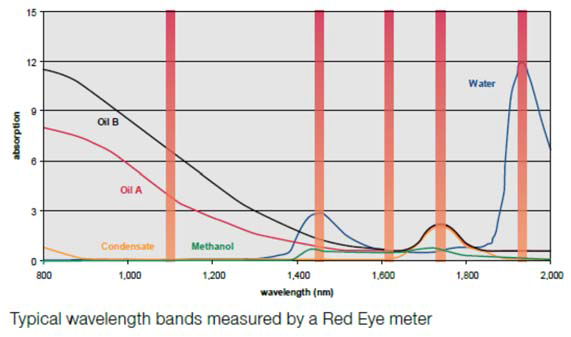

The principle of infrared absorption method is based on near infrared absorption spectra. By analyzing the spectral lines at characteristic wavelengths in the near infrared, it is easy to distinguish between media such as moisture, crude oil, and methanol. See the figure below.

The salinity of the crude oil has no effect on the measurement because only the water molecules absorb infrared light and the salt in them has no effect on the absorption. Gas also has no absorption to the characteristic wavelength of water measurement, so this method is also insensitive to gas (can measure the gas content up to 99.9%). Emulsion layer and sand and gravel have an effect on the full wavelength, which can be removed as background noise. The disadvantage of infrared absorption method is that the accuracy can not be done very high, the highest accuracy of 0.2% (absolute value), and are point measurement, if the pipeline oil and water mixing is not uniform, the measurement will not be representative. And electromagnetic wave and microwave method of water content meter can reach 0.05% (absolute value) or more.

2.2.3 Electromagnetic wave capacitance method

Based on the principle of electromagnetic wave RF absorption and frequency shift measurement. The measurement medium is placed as a dielectric between the poles of the electromagnetic wave heterodyne antenna. The structure of the antenna may be pointed, striped or comb shaped with wear protection. If high frequency energy is supplied to the antenna, the curved electromagnetic field lines will penetrate the measurement medium. The difference of water content in the medium will cause the change of RF field. Since water is a polar molecule, its relative dielectric constant is 70, and the dielectric constant of crude oil paraffin is 2.15~2.2. The total dielectric constant is linearly proportional to the water content and capacitance C. The water content in crude oil can be calculated by detecting the change of RF field through the interrogator, and then by temperature compensation and data transmission evaluation.

The characteristics of the method are: built-in temperature compensation to compensate for changes in dielectric constant caused by temperature changes; salinity has no effect on the measurement through amplitude control; no effect on the measurement when the solid content is <5%; entrained gas has no effect on the measurement when the water content is less than 5%; the measurement depth is 150mm and the average moisture in the range can be measured; 0~100% water content can be measured; density compensation can be performed.

2.2.4 Microwave absorption method

Based on the principle of absorption of microwaves by polar water molecules. The shared electron pair in the middle of the water molecule is biased toward the oxygen atom side, so that the two ends of the water molecule have a positive and negative charge, so the water molecule is a polar molecule. When the polar water molecules in the high-frequency microwave electromagnetic field, the poles of the water molecules will change direction and change position correspondingly and quickly, thus generating heat by mutual friction, so the water molecules can absorb microwave energy. And crude oil and other hydrocarbons for non-polar molecules, the absorption of microwaves is very little.

By measuring the change in frequency before and after the microwave through the medium, the mixed dielectric constant of the medium can be obtained, as the dielectric constant of water is close to 70, the dielectric constant of crude oil is 2, the water content in crude oil can be introduced. By measuring the change of energy before and after passing through the medium, it can be judged whether it is water continuous phase or oil continuous phase. The method has high requirements for factory calibration, the oil continuous phase and water continuous phase should be calibrated separately, and the influence of temperature and salinity should also be considered. As the temperature and the mixed dielectric constant into the inverse change, so the need for compensation. And salinity will cause dielectric loss, also on the mixed dielectric constant impact, also need to consider compensation. It is also possible to calculate the water content by supplementing the microwave transmitting antenna with energy, keeping the frequency constant, according to the amount of supplemental energy.

The method of loading DC to determine whether the water continuous phase or oil continuous phase. This form of antenna is generally a point measurement, which requires oil and water to be fully mixed. Oil continuous phase and water continuous phase measurement using two antennas, measurement of oil continuous phase and the same method described previously, measurement of water continuous phase is based on the Maxwell formula, measurement of conductivity and then calculate the water content [3].

Maxwell formula: S = 2p/(3-2p) * S1

where

S------- for the conductivity of crude oil containing water

S1------- is the conductivity of water

p------- is the water content of crude oil

2.2.5 Microwave resonance method

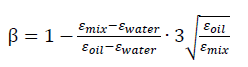

Is also based on the principle of polar water molecules on the absorption of microwaves. The difference with the microwave absorption method is through the scanner table frequency band, to determine the microwave resonant frequency, and then by calculating the mixed dielectric constant, and then according to the Bruggemann equation to calculate the water content.

Bruggemann equation:

Where: β is the water content of crude oil, εmix is the mixing dielectric constant, εwater is the water dielectric constant, and εoil is the crude oil dielectric constant. This method is characterized by the direct calculation of the mixed dielectric constant by the microwave resonance frequency, and to get more accurate measurement results can be accessed to the densitometer for iterative calculation. The densitometer is used for estimation when measuring the continuous phase of water. Salinity also has an impact on the measurement and requires the addition of a conductivity measurement function to compensate.

The disadvantage is expensive, need to add a densitometer or mass flow meter to measure density to get high accuracy.

2.2.6 Radiofrequency method

Measurements are made according to the different absorption coefficients of oil, water and gas for rays. The density of the medium is different, the absorption coefficient of the rays is different, and the half-life layer is different. According to the Lambert-Bell formula, the dose change of rays before and after passing through the medium is measured and the average density is calculated. The water content is then calculated based on the average density, the density of crude oil, and the density of pure water.

The disadvantage of this method is that there is a statistical error in the dose measurement of rays, so the accuracy is not high. It is also not recommended because of the radiation source and the time-consuming and laborious maintenance.

2.2.7 Density method

The water content is deduced from the average density, as well as the density of crude oil and the density of pure water. The ray method is one of the density methods, and there are also methods using mass flow meters or densitometers. The density method is only applicable to the occasion of no impurities and small gas content, otherwise it will cause great errors.

2.3 Effect of installation on online measurement of crude oil water content

According to ISO 3171 - Automatic sampling method for petroleum liquid lines, crude oil water content sampling must ensure that the liquids are homogeneously mixed, a requirement that also guides online measurements. The antenna only measures the liquid within a certain range of contact with it, so the liquid must be homogeneously mixed. The flow rate and pipeline components can be used to mix the liquid, and in many cases where conditions are not available, static mixers or power mixers need to be considered.

Mixed components | Piping direction | Min. pipeline flow rate 0 0.3 0.6 0.9 1.2 1.5 1.8 2.1 2.4 | ||||||

| Power Mixer | Horizontal or vertical | Any flow rate | ||||||

| Static mixer | vertical | Layering | unpredictable | Sufficient dispersion | ||||

| Static mixer | Horizontal | Layering | unpredictable | Sufficient dispersion | ||||

| Pipe fittings | vertical | Layering | unpredictable | Sufficient dispersion | ||||

| Pipe fittings | Horizontal | Layering | unpredictable | Sufficient dispersion | ||||

| Pipeline | Horizontal or vertical | Layering or unpredictable | see C2e) | |||||

2.4 Summary

The measurement of crude oil water content has been paid more and more attention because it affects the cost accounting and other economic factors of enterprises. Because of the early use of its working conditions and instrumentation requirements are not given enough attention, resulting in the general use of bad. According to the above analysis of several common measurement methods, as well as special attention to the installation requirements, we hope to help the selection of the instrument.

3 Conclusion

When choosing a water in oil measuring instrument, it is important to first understand the medium of measurement, requirements, and then choose a suitable solution based on the principle, measurement range, and influencing factors. Dissolved water in oil as well as water content of crude oil should not be mixed up.